Gauge Valves are available gauge connections

Application used

Working pressures

Advantage

In case of gauge glass breakage, stainless steel ball checks to shut off the flow automatically.

Ball valve is a quarter turn operated valve. The closure member is a spherical plug with a through hole. When the valve is in open state, the through hole is in-line with the fluid flow and hence, the fluid passes through it. The valve is closed by rotating the globe by 90 Deg. such that the hole now becomes perpendicular to the flow and hence, stops the flow.

The seat is usually circumferential, made up of soft materials to offer a tight shutoff. The seat can be made either out of plastic or metals. Ball valves are not recommended to be used in a partially open condition. Due to misalignment between the flow direction and opening of the plug, large pressure drop takes place in partially open condition.

Butterfly valves are most simple yet versatile valves. They are quarter turn operated valves which are commonly used in multiple industries for varied applications. Quarter turn operation ensures quick operating of the valve. In the open condition there is minimum obstruction to the fluid flow through the valve as the flow passes around the disc aerodynamically. This results in very less pressure drop through the valve.

Due to its unique mode of operation, the valve can be actuated easily without requiring high torques and wear and tear. Due to lack of friction, use of bulky actuators can be avoided. Another advantage offered by butterfly valve is their compact size. The valve is quite compact, resembling a metal disc. This makes their installation very easy.

Globe valve is a linear motion type of valves and is typically used in both on-off and throttling applications. In globe valves, the flow of the fluid through valve follows an S-path. Due to this, the flow direction changes twice which results in higher pressure drops. Due to other advantages offered by them, they are widely used in applications where pressure drop through the valve is not a controlling factor.

These valves are generally not used beyond sizes larger than NPS 12 (DN 300) as enormous forces are exerted on the stem to open or close the valve under fluid pressures. Globe valves require high pressures on the seat to keep it closed when the fluid exerts pressure from the bottom of the disc.

Disc check valves, also called as non-return valves allow the flow to pass through them in only one direction and stop the flow in reverse direction. Because of this unique directional property, disc check valves are essentially used for some critical applications in the steam systems.

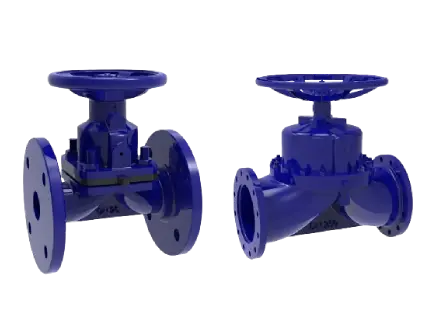

Gate valve is a sliding type of valve. In gate valves, the closing member is a metal gate. The gate slides down to close the valve. In fully open conditions, the flow area is equal to the area of the pipe and hence, there is negligible pressure drop across the valve.

Gate valve should ideally be used as on-off valve. It is not advisable to use them as throttling valves because in partly open conditions, erosion of gate might take place. In partially open consitions, due to vibrations, valve is exposed to quick wear and tear. Also, during closing and opennig, there is considerable amount of friction and hence, opening and closing these vales quickly and frequently is not possible.

Similar to ball valves, plug valves are also quarter turn type of valves. This valve consists of a plug which can be either cylindrical or conical in shape. The plug has a through slit which remains in-line with the flow in the open condition. When the plug is turned by 90 Deg., this slit becomes perpendicular to flow and the valve gets closed.

Plug valves are well suited to handle fluids with suspended solids, slurries etc.

The exterior of the stem is threaded, while the portion of the stem in the valve is smooth. The stem threads are isolated from the flow medium by the stem packing. Two different styles of these designs are available; one with the handwheel attached to the stem, so they can rise together, and the other with a threaded sleeve that causes the stem to rise through the handwheel. This type of valve is indicated by "O. S. and Y." is a common design for NPS 2 and larger valves.

The threaded part of the stem is inside the valve body, and the stem packing along the smooth section that is exposed to the atmosphere outside. In this case, the stem threads are in contact with the flow medium. When rotated, the stem and the handwheel to rise together to open the valve.

The threaded part of the stem is inside the valve and does not rise. The valve disc travels along the stem, like a nut if the stem is rotated. Stem threads are exposed to the flow medium, and as such, are subjected to the impact. That is why this model is used when space is limited to allow linear movement, and the flow medium does not cause erosion, corrosion or abrasion of the stem material.

This valve stem does not rotate or turn. It slides in and out the valve to open or close the valve. This design is used in hand-operated lever rapid opening valves. It is also used in control valves are operated by hydraulic or pneumatic cylinders.

This is a commonly used model in ball, plug, and Butterfly valves. A quarter-turn motion of the stem open or close the valve.

In the main Menu "Valves" you will find some links to detailed (large) images of Rising and NON Rising Stem valves.

With this part you will learn how to use the Base Flange feature. This adds all Sheet Metal features and functions in one step. You are able to edit material thickness, material direction, extrude type, bend radius, bend allowance, auto relief, and the ability to use gauge tables.

A These are made using quality carbon steel that results in long lasting performance. Our range finds applications in different industries, such as cement and construction, pumps and petrochemicals and is offered in different dimensions to our clients. We also customize our range to suit the various requirements of the clients.

Guide bush work is one of the most creative areas of routing but one of the most neglected. A guide bush is one of the standard accessories supplied with nearly all routers, but reaction from my course students suggests that in many cases it remains unappreciated and unused. There are, of course, a number of well-known commercial applications such as dovetailing, lettering...

We are enlisted amongst the top names in the industry engaged in offering a quality approved range of Textile Machinery Spare. These are widely used in various applications and are well known for their dimensional accuracy. These are made using fine quality material and advanced methods under the supervision of our highly skilled professionals. Besides, we also assure safe and timely delivery of our products.

We are offering a wide range of power tiller components. These components allow each wheel to move independently of the other, without a continuous axle shaft between them. These are made of fine quality material and are available in competitive prices.

Ellem Engineering has experienced healthy growth over the last few years in manufacturing Automobile Components that are widely used in Automobile industries all over India. Our products are manufactured by expert engineers at technologically advanced manufacturing unit in Coimbatore. These are widely appreciated for features like Robust construction, corrosion resistance, abrasion resistance and dimensional accuracy.

Automobile Parts offered by us is highly demanded in various residential and commercial sectors. The offered Automobile Parts are extensively used in car & truck parts for most makes and models of automobiles. Further, the offered products are available in the market in bulk at reasonable rates.